Description of the Disdrometer RD-80

Specifications | Sensor Installation

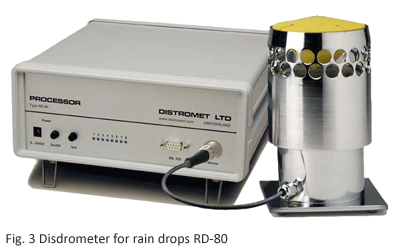

The disdrometer for rain drops consists of two units: the sensor, which is exposed to the rain and the processor for analog processing and digitizing of the sensor signal. A cable, 4 meters long, is used to connect the two units.

The disdrometer for rain drops consists of two units: the sensor, which is exposed to the rain and the processor for analog processing and digitizing of the sensor signal. A cable, 4 meters long, is used to connect the two units.

The sensor transforms the mechanical momentum of an impacting drop into an electric pulse, whose amplitude is roughly proportional to the mechanical momentum. It is housed in a cylindrical case, which protects the sensitive parts.

The processor contains circuits to eliminate unwanted signals, mainly due to acoustic noise, to reduce the 90 dB dynamic range of the sensor signal and to digitize it into a 7bit code.

A block diagram of the whole system is given in Fig. 4.

The sensor consists of an electromechanical unit and a feed-back amplifier housed in a common case. A conical styrofoam body is used to transmit the mechanical impulse of an impacting drop to a set of two moving coil systems in magnetic fields.At the impact of a drop the styrofoam body together with the two coils moves downwards and a voltage is induced in the sensing coil. This voltage is amplified and applied to the driving coil, producing a force which counteracts the movement.As a consequence the excursion is very small, and it takes very little time for the system to return to its original resting position and therefore to get ready for the next impact of a drop. The amplitude of the pulse at the amplifier output is a measure for the size of the drop that caused it.

The sensor consists of an electromechanical unit and a feed-back amplifier housed in a common case. A conical styrofoam body is used to transmit the mechanical impulse of an impacting drop to a set of two moving coil systems in magnetic fields.At the impact of a drop the styrofoam body together with the two coils moves downwards and a voltage is induced in the sensing coil. This voltage is amplified and applied to the driving coil, producing a force which counteracts the movement.As a consequence the excursion is very small, and it takes very little time for the system to return to its original resting position and therefore to get ready for the next impact of a drop. The amplitude of the pulse at the amplifier output is a measure for the size of the drop that caused it.

The processor has three main functions:

- it supplies power to the sensor,

- it processes the signal from the sensor and

- it contains circuits for testing the performance of the instrument.

The signal processing circuit consists of four parts:

- a noise rejection filter,

- a dynamic range compressor and

- a signal recognition circuit.

- a non-linear A-D-converter

The noise rejection filter is an active band pass filter, whose frequency response is designed to give an optimum ratio between signals from rain drops and signals due to acoustic noise affecting the sensor.

The noise rejection filter is an active band pass filter, whose frequency response is designed to give an optimum ratio between signals from rain drops and signals due to acoustic noise affecting the sensor.

The dynamic range compressor uses an operational amplifier with a voltage dependent feedback network to get the desired characteristic.

The signal recognition circuit can distinguish between the signal pulses caused by drops hitting the sensor and the more uniform oscillations caused by acoustic noise. If a pulse caused by a rain drop exceeds the oscillations caused by noise, a gate passes it to the pulse standardizer, which produces a constant pulse duration without changing the amplitude of the original pulse.

The non-linear A-D-converter produces a 7-bit code for every drop hitting the sensor.